In the early 1960’s the idea of polyethylene plastic being used as a substitute for ice was born, with the world’s first commercially viable synthetic ice product launching in 1978.

The polymers used back then, although state of the art at the time, were not great for skaters. They could not glide smoothly on the surface without the regular application of a silicone compound or alternative lubricant. Even then, it did not have the smooth glide of regular ice.

Our subsidiary company history, NOICEONE, goes back to the 1980’s – the first full size synthetic skating rink was installed in Southport, UK introducing a patented interlocking panel made of a higher density polyethylene. It was truly revolutionary. The surface still needed to be sprayed regularly with a gliding fluid to be maintained, but advancements in panel connection systems and skateable materials were slowly being made.

Into the 1990’s, NOICEONE was the worldwide front runner in manufacture, design and installation around the world, and is still working away today developing innovative new products and improving materials. SmartRink has had the direct benefit of both past achievements of NOICEONE and been directly involved in more recent engineering advancements of this product and want to share some of the things we have learned.

Most synthetic ice suppliers today are still using mass produced extruded polyethylene material. This product may have evolved over the years, however it certainly doesn’t meet the SmartRink quality standards for GLIDE, PERFORMANCE and DURABILITY.

Having over 40 years experience in the industry, we have been heavily involved with testing of various products on the market. Our German manufacturer (OKULEN) completes continuous in house research, development and engineering to maintain a world renowned product that is second to no other.

Here is a brief overview of accomplishments:

- First commercially viable product for sale in 1978

- Developed and patented the H-Tongue connection system

- Popularized the synthetic ice Home Rink Advantage selling rinks to homeowners in Canada and USA

- Sold and installed the world’s first permanent NHL size rink (still in operation).

- Installed the world’s largest backyard synthetic ice rink (we think it still has the record)

- Designed and patented the world’s first Hybrid-Lock(TM) connection system

- Developed in conjunction with our partners the only officially endorsed ice less curling system by the World Curling Federation

- Invented the world’s only inter-connected 2 sided goal crease

- Sold the first ever synthetic ice skating rink to Barbados

- Developed the world’s only true comparison measurement test tool : The Weighted Skate Test (TM)

- Developed our trademark Ice-Y-Blue700(TM) skating material

On to Today:

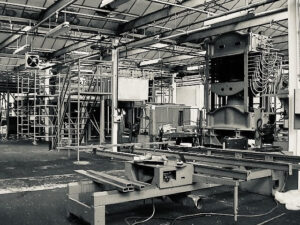

Our premium grade panel uses a Very High Molecular Weight Pe virgin resin as raw material and then is sinter pressed (a process that uses extreme hot and cold pressure to ensure an extremely dense material). Our Exclusive producer partner, OKULEN, has a meticulous DIN ISO9001 quality system in place, which consistently produces an exceptional skating panel every time! The process ensures no gaps or air pockets, only a solid homogeneous sheet. During the process the material is de-stressed so that it always lies flat.

Synthetic ice is used all over the world as a replacement for real ice. Without the need for refrigeration, electricity or heavy equipment, the environmental impacts are substantial, offering an environmentally sustainable and eco-friendly alternative. At the end of the useful life of our material, it can even be ground up and reprocessed