Monthly Archives: February 2015

Industry Testing

I’ve been fortunate to work closely with experts from this industry who have been working with engineered polymers for 35 years or more. There are a few other companies out there also claiming to have been in the industry that long as well. So it is really surprising when I read on their company websites complete and false untruths about products in our industry. Especially when their claims are without merit, and not based on any kind of synthetic ice industry testing

In the case of one company – published on their website is information about UHMW material which is shockingly erroneous and absolutely false. Credibility needs to be questioned when information is this wrong. For example one site indicates that “UHMW is much too hard to allow a skate blade to penetrate the surface sufficiently. Light weight skaters will not penetrate the surface to any degree”.

When anyone indicates that UHMW is too hard for skating that is actually a sad statement. UHMW stands for Utra High Molecular Weight and should correctly be followed by Pe which stands for Polyethylene. The industry typically designates any molecular weight resin above 1 million grams per mol as UHMWPe and can be as high as 4 million or higher. Just as there are various molecular weights within HMWPe, HDPe and LDPe classifications. All of these products have been used for synthetic ice.

As the molecular weight of the material increases the product actually gets “softer” not harder as has been inaccurately written about on the site in question.

There are very standard test procedures in the plastic industry that measure the “hardness” of products. This particular company would be well advised to understand them and then compare their material to them.

This page also goes on to mention UHMW is used in the lining of truck beds. Well that is actually true, just as UHMWPe is used in literally thousands of other applications such as hip joint replacements, valve coatings, ski and snowboard bases and numerous other industry applications that require the very best abrasion resistant material combined with material with the best coefficient of friction ratings. But to say UHMWPe is used for truck beds as a general statement is akin to saying extruded HDPe is used for arena board or puck board, or cutting boards!

We do agree on one thing – UHMWPe is not the best material for skating – but we absolutely disagree on why. Their claim is because it is too hard for skating on, and there could be nothing further from accuracy than that! UHMWPe is in fact too “soft” for skating.Remember that as the molecular weight increases the material becomes softer, not harder!

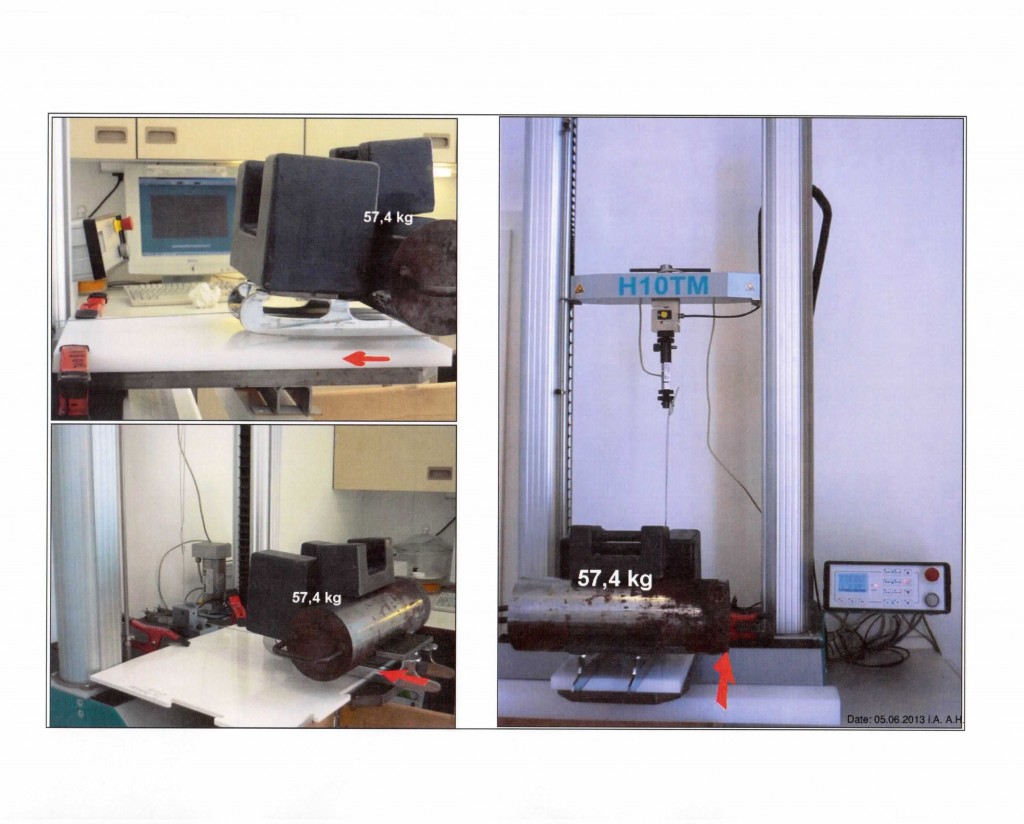

In our weighted skate tests for example – we have proved over multiple tests and trials that UHMWPe is not the best choice for skating as the skate blades tend to sink in too much and therefore the product will feel “sluggish” and slower for skating. Perhaps a light child will not notice that but a 200 pound skater certainly will. Read more about our synthetic ice research.

So where does that leave us in terms of what to believe? It’s really very simple, when you are doing your research, ask the supplier company to supply you with all the following information which is the only way you can truly determine and compare numbers:

1) Weighted skate material trials

2) Shore-D (Shore Durometer) hardness tests

3) Abrasion resistance tests (sand slurry test for example)

Ideally all materials are submitted to a third party lab and subjected to identical tests and that would go a long way to clearing the air on various materials. Ultimately the market will dictate what is used for skating and what isn’t – but please consumers – be smart and do your research on synthetic ice rinks.